A pair of ancillary aviation buildings in Norway, designed as efficient, acoustically insulated machines, flexible for the future.NorwayTravelWork

Qualify

Conceive

Refine

Realise

Revisit

Haptic was commissioned to build two service stations at the airports of Kristiansund and Bergen on the west coast of Norway.

We won the project in competition, seeing it as a good opportunity to build our aviation experience with the support of colleagues at Nordic, who are on the Norwegian aviation authority’s design framework.

At Bergen, the building is one of the first built projects in a new masterplan, so its location, orientation and design have to be flexible as the context changes.

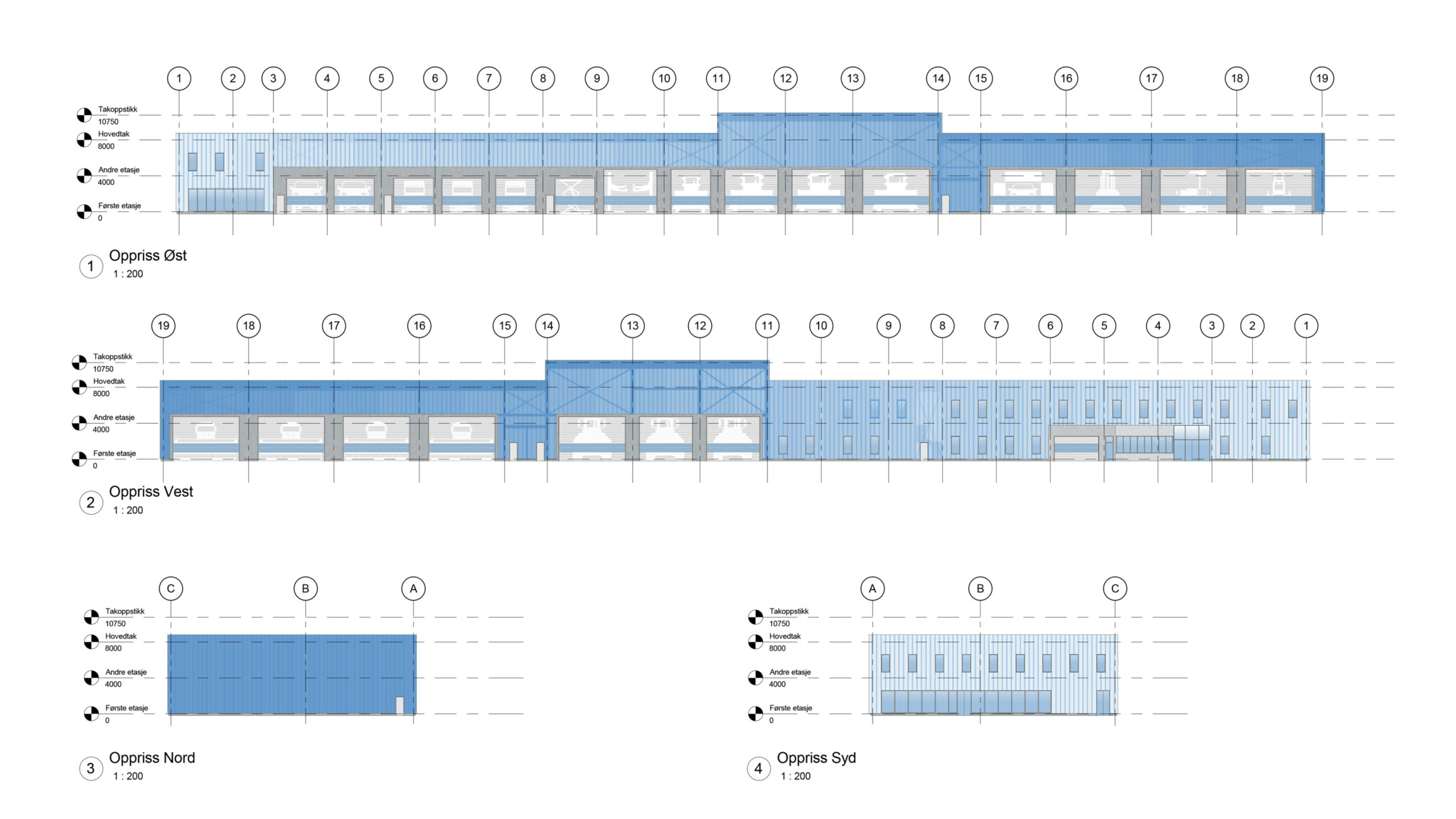

The buildings have workshops to service airport vehicles such as the 20-metre-long ploughs that are essential in keeping Norway’s runways free from snow. At Kristiansund, the building also includes a fire station.

The brief was for a simple structure that would perform well environmentally, offer flexibility in the future, and that was insulated against the considerable noise of the airport runways.

Our design solution is super-pragmatic, the architecture pared back so that the budget is used where it matters most.

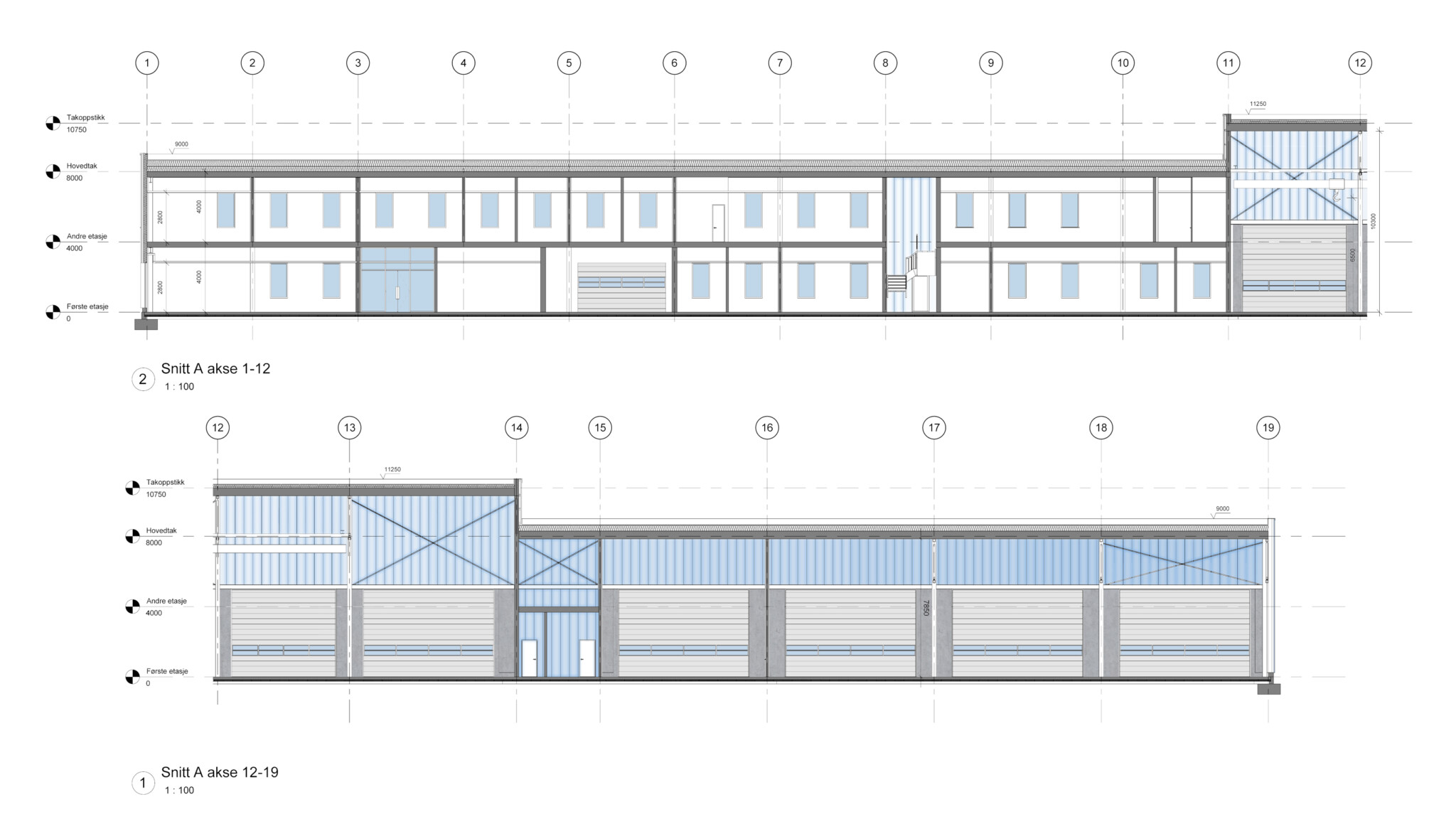

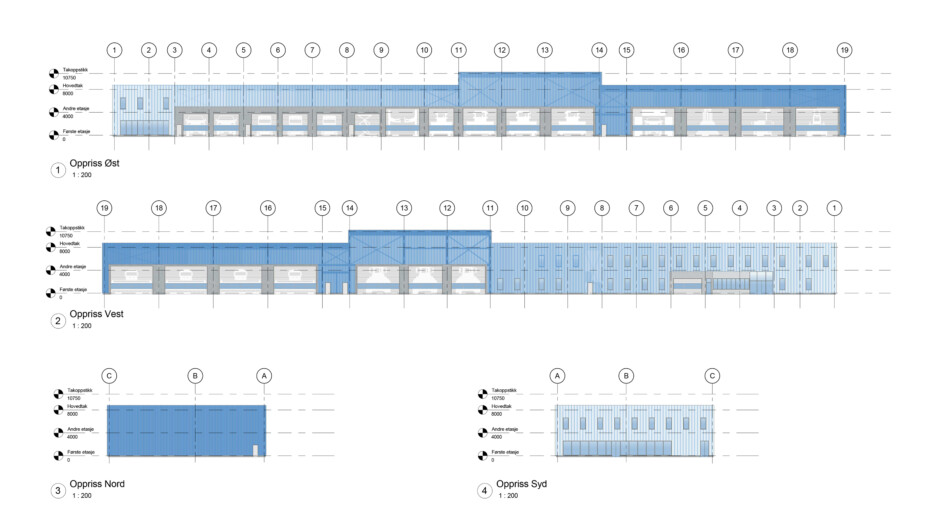

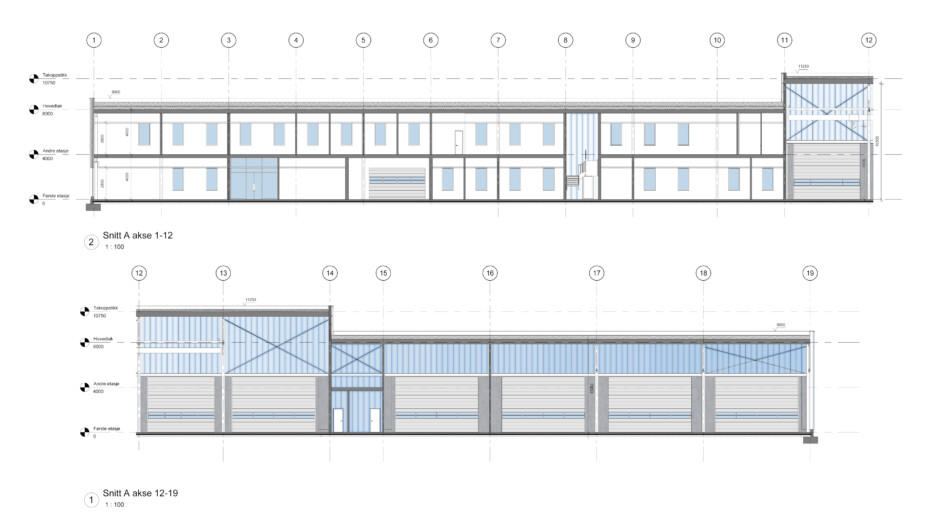

The simple building is easy to repeat and has an expandable steel structural system: modules can easily be added to extend the space.

We worked with our client to develop the programme for both buildings, bringing a complex array of functions – admin and teaching spaces, control rooms, workshops, offices and garages – into a simple, contained box.

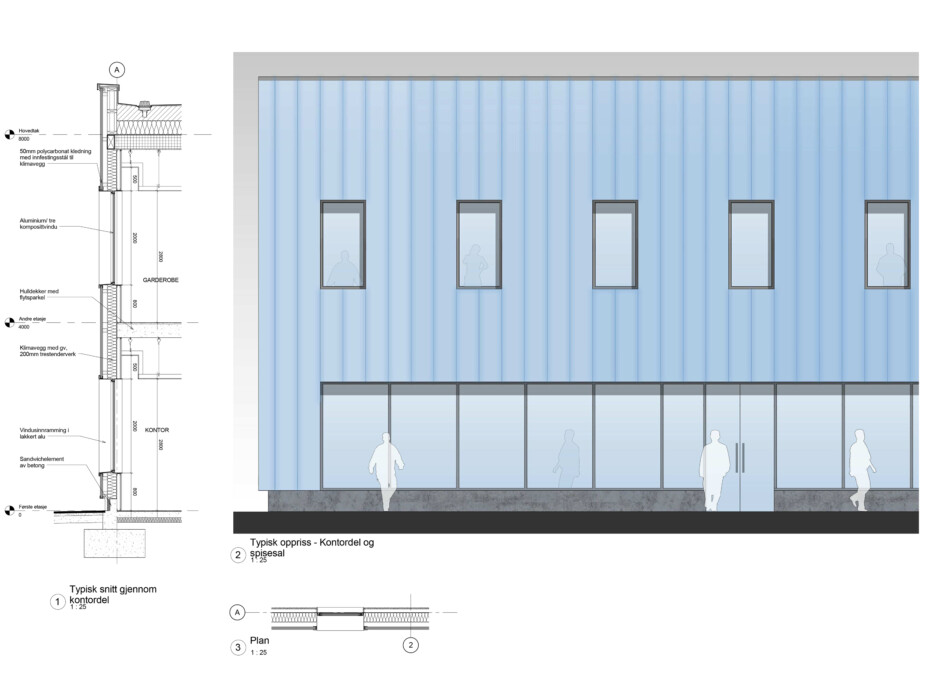

To meet the very strict acoustic standards required, particularly at Kristiansund where the building also houses the airport administration, we created a highly insulated building, sealed against the noise.

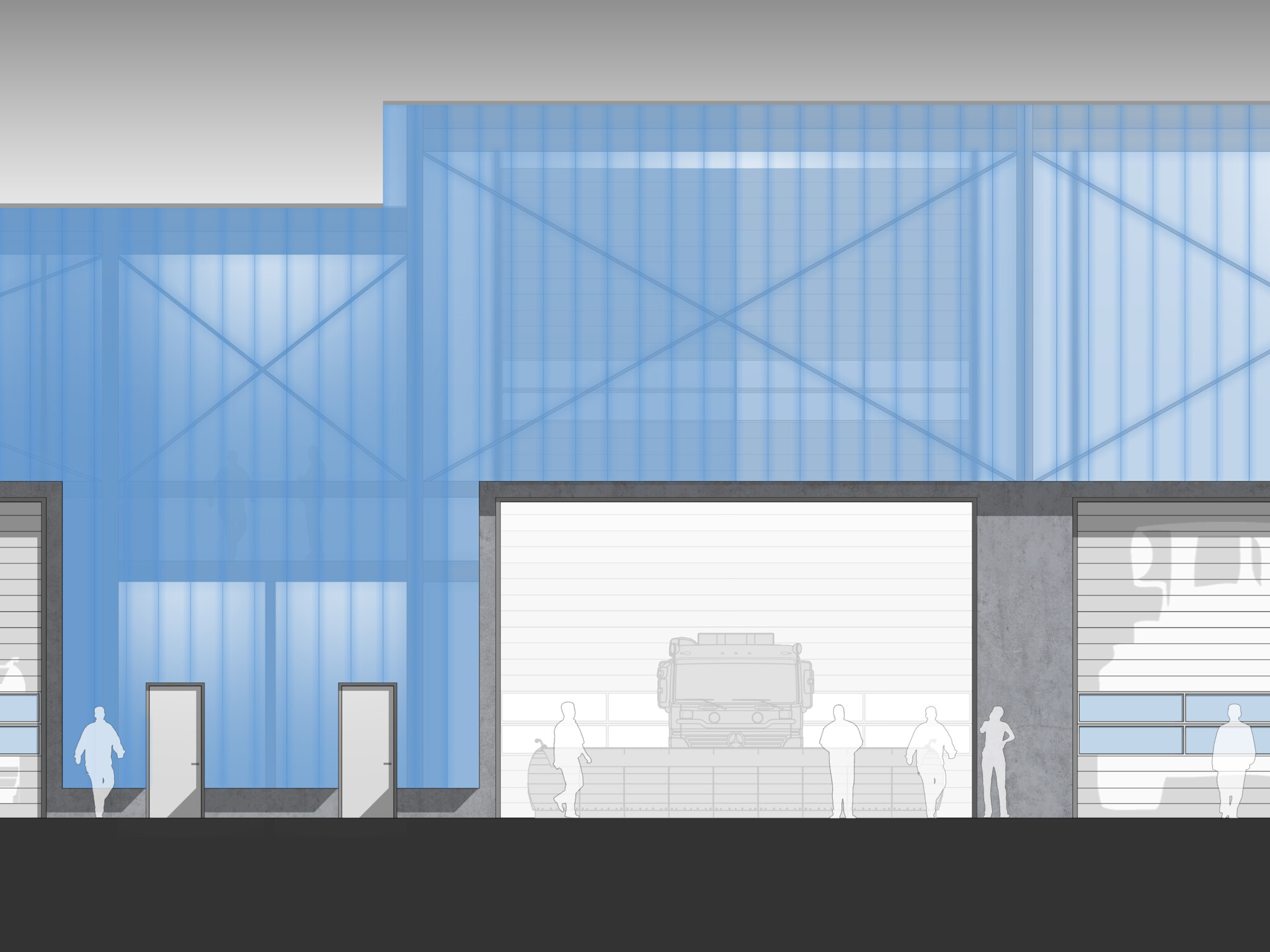

The steel-framed building at Flesland has a translucent wrapping of layered polycarbonate, sandwiched with air gaps to improve its acoustic performance.

The blue tone of the polycarbonate reflects the landscape of fjords and mountains, blending into the clear sky.

The polycarbonate lets a diffuse light into the garages and workshops inside, creating a high quality working environment.

The cladding has a high u value so it performs well environmentally.

The modular system was straightforward to build on site, and is similarly easy to repeat by adding further bays or floors as demands for ancillary services at both airports change in the future.

Our work at Flesland and Kristiansund reflects our approach to other industrial buildings where the budget is tight and the programme complex: by keeping things simple we can achieve an efficient machine but a good working environment.